Bushing-type Sizing Dies - RELOADING BASICS

-

0

Comments

Comments

- Last updated: 28/02/2024

In an ideal world, when you seat a bullet into a bottlenecked rifle case, the case neck should grip the bullet adequately without the need for any additional crimping. The amount of grip, known as neck tension, must be consistent (to ensure consistent chamber pressures), and strong enough to keep the bullet in place during handling and chambering.

When cases are resized, either full-length or neck-only, with a standard resizing die, it squeezes the neck of the case down to a predetermined size, which is generally sufficient to give ‘adequate’ neck tension for the ‘average’ case/bullet combination. You can, however, buy a die with interchangeable bushings, allowing you to control and vary the amount of neck tension.

Variables affecting neck tension

Cases from different manufacturers, and even cases from the same manufacturer, but from different batches, can have different brass thicknesses at the case neck. When case necks are resized, either internally or externally, the dimensions of the die are constant, so if the thickness of the case is different, the effect of the resizing will be different. If a much thicker brass case neck is squeezed down to size from the outside, then the resulting internal diameter of the case mouth will be smaller than that of a case with thinner brass resized in the same die.

Not all bullets that can be used in a given calibre are of the same diameter and, although the differences can be very small (down to 0.001”), different bullet diameters will be held differently by the same amount of neck tension.

Standard dies

Most resizing dies that come in a die set will resize the cases to a set diameter for that calibre, most often related to the SAAMI dimensions for cases. The resized cases will work just fine and will almost always hold the bullet firmly. The downside of this type of die is that you cannot alter or experiment with the amount of neck tension to improve the performance of your ammunition.

Bushing-type full-length resizing dies

This type of die utilizes interchangeable bushings that come into contact with the neck portion of the case during resizing and squeeze it down to the size of your choice, within a given range for the calibre. The bushings are inserted and switched over through the top of the die and changing them takes just a few seconds.

L. E. Wilson makes a full-length sizing die with interchangeable bushings in a wide range of calibres, and there are several different bushing sizes available for each one.

Calculating the correct bushing size

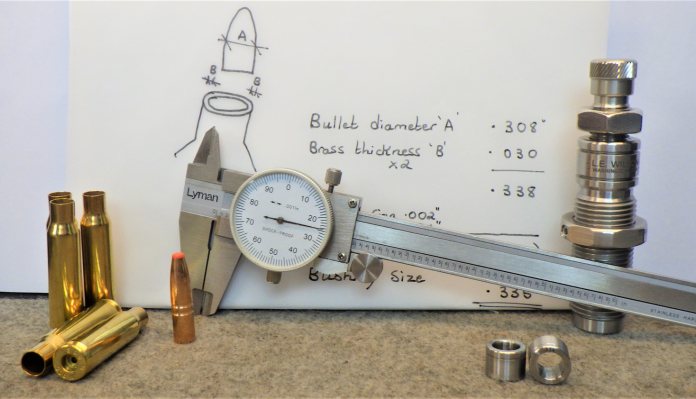

Typically, adequate neck tension is achieved when the internal diameter of the case neck is 0.002” smaller than the outside diameter of the bullet. This isn’t cast in stone as the best across the board, but it is a good starting point. If you know the external diameter of your bullet, and you measure the thickness of the brass at the neck of your case, you can calculate the correct bushing size to use to give the required neck tension, as follows:

Add the diameter of your bullet to twice the case wall thickness to give you the outside diameter of your loaded round at the case neck. To grip this diameter, you want to deduct 0.002” for neck tension, and a further 0.001” to allow for the brass to spring back after the resizing process. You therefore deduct 0.003” from the outside diameter of your load and the resulting figure is the size of the neck bushing you require.

It is important to remember that you need to repeat the calculation every time you change the brand of cases or the brand/size of the bullet you are using. The purpose of this type of die is to give you more precise control over neck tension and it will be different for each combination of components.

Experimenting

Sometimes, increasing or decreasing neck tension can have a significant effect on your home loads and, within reasonable limits, you can change the size of the neck-bushing you are using to see what happens. If you are using a calculated bushing size of, say .335”, you can safely try .334” or .336” and the muzzle velocity and consistency of your ammunition will change.

As you increase neck tension, you are increasing the grip that the case has on the bullet, and the powder burning inside the case will have to generate more pressure to overcome that tighter grip. Increasing the chamber pressure in this way should be approached carefully and you need to watch for signs of excessive pressure. Reducing neck tension will lower chamber pressure and muzzle velocity.

If you try to apply too much neck tension, and size case mouths too small, you will make it impossible for the bullet to enter the case mouth smoothly and risk damaging both the bullet and the case. Applying too little neck tension will mean that the bullets are not held tight enough, and they could be pushed back into the case while being handled or chambered, which could result in a dangerous level of chamber pressure.

Conclusion

A resizing die with interchangeable neck-sizing bushings gives you the opportunity to experiment with different amounts of neck tension and fine-tune your ammunition. It is a variable that can have a significant effect on how well your ammunition performs, and this type of die also allows you to keep the neck tension the same on any ammunition you make, even if using different cases or bullets. Taking a factor like neck tension and being able to control and standardise it to suit your cases and bullets, means that you can optimise the performance of your reloaded ammunition and remove this particular factor from the list of variables.

Contacts:

L E Wilson – www.lewilson.com

Reloading Solutions Ltd - www.reloadingsolutions.com