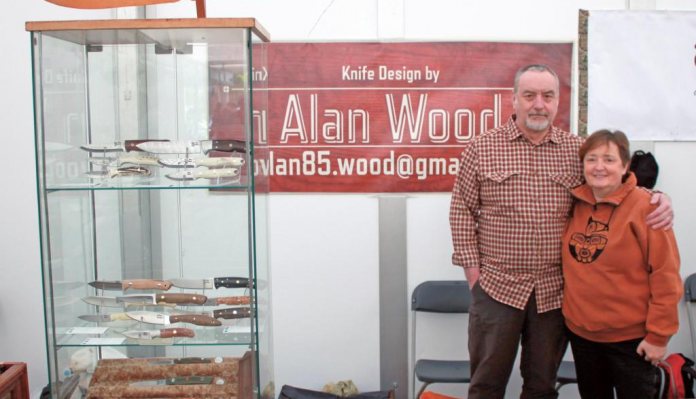

Alan Wood Knives

-

13

Comments

Comments

- Last updated: 23/07/2019

There are few U.K custom knife makers that can claim to have a better reputation than Alan Wood. He has been making custom knives professionally since 1985; his knife making started when he was about 11 years old, after he had seen on TV the 1952 film ‘The Iron Mistress’. This Alan Ladd western was about the legend Jim Bowie and heavily featured the large knife named after him and young Alan just had to have a knife, like Jim! He set about making one in his Dad’s shed, this was even before he had done any metal work classes at school; suffice to say, it was not a massive success, but the seed was set.

The real turning point in Alan’s knife making came when he found the book ‘Knives and Knifemakers’ by Sid Latham; this book from the U.S.A was first published in 1973 and he still has the book today, such was the impression it had upon him. It highlights various aspects of knife making and collecting, also touching on maintenance, sharpening etc. It features American makers such as Loveless, Moran, Chappel, Dozier, Hale and Sigman. It was the first book he had seen that detailed how to make a knife, the right way. He found that he was good at it and, more importantly, loved the process and the result. In 1985, after dabbling as a craft teacher, which he hated, he decided to go full time knife making. This was in the days of Margret Thatcher’s Enterprise scheme, which paid him a £40 a week wage, if he put up £1000 and had a business plan. He borrowed the money from his Father and got to work. I first came across him in the pages of Guns and Weapon’s magazine in 1987. He wrote articles on his knife making for them, which I loved. I contacted him and he made me a homage to my favourite knife, the Randall Model 14. It is a masterpiece and, of course, I still have it today. When it came to my shooting activities, I of course wanted a rabbiting knife made by Alan, which he made to my design. In 1995 he then made me a more general shooting/camping knife, again to my own design, which I used when shooting in Yorkshire, Wales and Scotland many, many times. I had two made, a ‘safe queen’ and a user.

Alan is in great demand as a knife designer, as well as a custom knife maker. He has links with the Woodlore knife now taken as THE knife for actual Bushcraft use. Ray Mears, the world-renowned Bushcraft and survival instructor contacted Alan, as he wanted a British knife specifically designed for Bushcraft. Alan made a prototype and Ray fed back minor tweaks based upon real world usage by skilled hands, such as himself, but also the raw students he was teaching Bushcraft skills to on a regular basis. Ray and Alan’s Woodlore design is much copied all over the world now by both custom and mass production knife makers. Alan still makes knives to the Woodlore profile today, although not for Ray’s Woodlore Bushcraft School. He makes both high end custom versions, which, let’s face it, will never be used, in Damascus steel with iron wood scales, all the way to 12c27 stainless steel blades and Micarta versions, which are real users. His finest O1 tool steel Bushcraft working knives are the best you can get. You have the opportunity to own a knife made by the original maker who had a hand in designing the now iconic blade/handle shape.

Scandinavian collaboration He also works with Casstrom of Sweden and they produce the Safari knife of Alan’s design. It came about as a knife for hunters of small deer species, such as Roe or Muntjac; its small dimensions are perfect for those. I had a long chat with Alan at the recent Northern Shooting Show and he showed me the knife set of his that is coming from Casstrom next. It’s a skinning set with a blunt-ended gutting knife and a longer hunter.

I asked what Alan’s favourite steel is and, straight away, he said 12c27, because it’s easy to keep sharp and anyone can get an edge on it; spoken by someone who has made working knives for a long time and for a lot of people. I asked him what he hated and it’s sharpening choils, “You don’t need them for sharpening and for working knives the choil gets full of fur and other stuff and limits using the whole blade”. Again, spoken from real world use of knives, I can see his point.

I’m privileged to own eight of his knives and attest to their quality and beauty. He makes about 50% Bushcraft knives and the others are Stalking/ Hunting knives. Waiting time for one of his custom-made knives is currently 12 months, although it may be less, depending upon what knives he has in the process at the time. Expect to pay from £260 up to £550, depending upon what materials/sheaths you want.

Alan Wood is a true gent and a master of his craft. He no longer produces a catalogue and has yet to set up a new website but tell him what you want a knife for and the size you like and he’ll offer a solution. Contact Alan: alan85. [email protected].