Reloading Basics - Prmier Pockets

-

14

Comments

Comments

- Last updated: 20/07/2022

Although the primer pocket is often the part of the case that gets the least attention, it is actually an important area and should not be neglected. As with every other aspect of reloading, uniformity is the key to consistent ammunition performance and the primer pockets play their part in achieving that consistency.

All reloading components are made to tight tolerances but sometimes a clash with these tolerances can occur and cause an issue with seating primers. Larger, within tolerance, primer pockets and smaller, but still within tolerance, primers are a bad mix, and vice-versa. It is important to get the right marriage of components to get the best out of your reloading. For the ideal combination, you are looking for primers that seat easily, but tightly enough to give an effective seal in the primer pockets.

If the primers are at the larger end of their tolerance, and the primer pockets are at the smaller end of theirs, then you will encounter problems with seating them. When you try to seat the primers, you can experience so much resistance that they are crushed or damaged before they are driven home. In extreme cases, you might seat a primer that is visibly damaged or flattened. It is also possible that the primers do not seat properly, with the feet of the anvil not engaged with the bottom of the primer pocket. This means that they are unlikely to detonate when the firing pin hits. This situation can be easily resolved by changing the brands of cases or primers you are using, or by swaging the primer pockets to enlarge them sufficiently to accommodate the primers you are using.

If primers seat very easily with little effort, they are probably far too loose a fit. It is very unlikely that primers can be so loose that they will fall out, and when they are fired they cannot be blown out because they are held in place by the bolt face. When the primer is ignited the cup will normally expand and this ensures a good tight seal between the primer cup and the primer pocket. If the primer fit is particularly loose, then it is unlikely to achieve an effective seal and when the round is fired, hot gases and pressure can blow back and escape between the two components. Evidence of this will appear as black sooty marks around the primers and also on the bolt face of the gun. In extreme cases, and with continued use of loose primers, this could result in possible erosion of the bolt face. The amount of pressure that escapes is difficult to quantify, as is its effect on the muzzle velocity of the bullet leaving the barrel, but any loss of pressure is going to affect the performance of your reloads and so is best avoided.

Primer hardness varies between brands and if you switch to a softer one, you will find that they seat easier and better in tight primer pockets. This is because they can squeeze into the tighter opening more easily. Harder primers will resist the attempt to squeeze them in and may collapse at the edge and deform. Experimenting with different brands is well worthwhile, to get the best match for your cases.

Each time you fire your reloads, small amounts of soot will be left inside the primer pocket and, over time, this can build-up to the point where it forms a cushion between the primer and the pocket. This then causes light strikes, where some of the force of the impact of the firing pin on the primer cup is absorbed by the cushion of soot and so the primer does not ignite. Although not always necessary every time you use the cases, the occasional cleaning of the primer pockets will prevent this from occurring. Both brush and scraper-type tools are available and both work well. Case tumblers and vibratory cleaners do not always get the primer pockets clean, so it is well worth doing them by hand.

Although brass cases are generally produced to very tight tolerances, some precision shooters will go the extra mile and use a primer pocket uniformer tool to ensure all of the pockets in a batch of cases are exactly the same size. These tools also effectively clean out the primer pocket, while they are shaping it to SAAMI specifications, but they do nothing to address oversized pockets and are perhaps a step too far for your average reloader.

A primer pocket swager is a tool intended to remove primer pocket crimps, often found on military surplus cases, but it can also be useful if you have a problem with tight primer pockets. The swager forces a punch into the primer pocket to displace the crimps around the edges so that it can be reprimed. The punch will ‘expand’ the edges of any tight pockets (to the standard size), while it is removing the crimp and this has been found to ‘standardise’ the diameter of uncrimped pockets, plus improve the seating of primers. If you have a batch of cases that you are struggling to prime, then it is well worth running them through a swager to ease the pockets a little.

Matching primers and primer pockets, so they fit together and function properly, will ensure that you get consistent and reliable ignition. If the brands you are using do not fit each other, then the easiest solution is to change one or the other to a different make, or you can purchase a tool to size and ease the primer pocket, but this can be time-consuming. Even when you have that perfect match, you may find that after several uses that the primer pockets become loose and less able to hold a primer securely (although cases typical fail elsewhere well before the primer pockets have gone loose) but until that day it is well worth looking after the humble primer pocket.

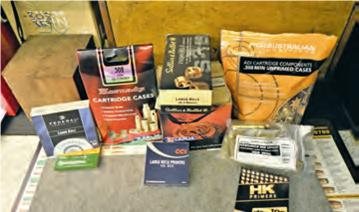

Lee Reloading Equipment - Henry Krank - www.henrykrank.com

HK Brand Primers – Henry Krank - www.henrykrank.com

Lyman Equipment– Hannam’s Reloading - www.hannamsreloading.com