Reloading - Shoe String Production

- By Wheelwrite

-

1

Comments

Comments

- Last updated: 21/12/2018

I’m focusing on those of you new to reloading, or not blessed with expensive kit that includes a chronograph. To save money and time, we’ll take a more empiric approach to the development process. However, some rules are immutable. The most important being the need to change only one variable at time.

It’s unlikely that you’ve started this process at the same time you bought your rifle; so, I’ll assume that you have a shooting application in mind and some experience with factory ammo. Your application sets a number of parameters for the development. For example, for deer hunting, we need to comply with specified minimum energy requirements. For paper punching, we need to establish the distances involved. For general and rapid fire use, we need to consider recoil. For pest control, we need to look at appropriate energy/stopping power and possible compatibility with a moderator. The design of the rifle will apply further constraints, with factors such as barrel length/twist and feed mechanism playing a role.

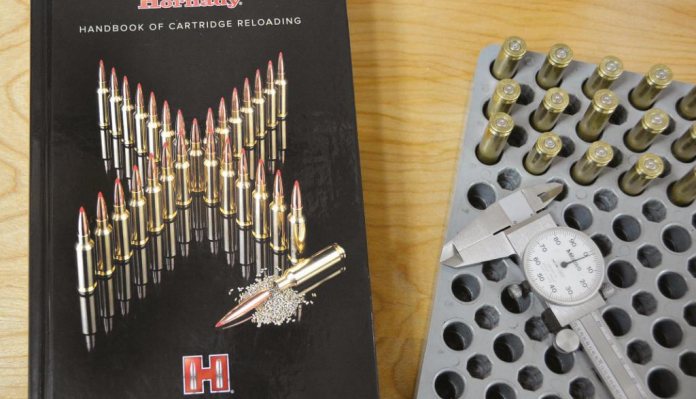

We need a couple of current reloading manuals, from those published by manufacturers of bullet brands that are readily available. Hornady’s Edition 10’s data is based upon real rifles (as opposed to test receivers) and it offers ‘best results’ comments for some calibres. Begin by selecting the most appropriate bullet for your needs, ensuring that its weight is compatible with the rate of twist and it’s fit for purpose. If your chosen bullet is from Speer, then refer to their manual for data. For powders, chose either their recommended type, or one that sits in the middle of the burn rate range.

If your barrel is much shorter than that of their test rifle, then you may wish to select a faster burning powder from nearer the top of the list. Try and avoid any with a load density of 1 (one) or greater, as working with compressed loads adds another small variable. If you’re seeking optimum velocity and energy, mindful of the effect on recoil, then you may select one that gave the highest figures during their testing. Some manuals quote a factory duplication load. If that squares with your desired requirements, you may wish to use that bullet, together with the listed powder as the basis for your first trials.

The choice of primer is not as important as the version that the manual recommends, such as a Magnum. Cases must all be of the same headstamp and ideally new or once fired in YOUR rifle. Only neck size them in order to ensure best chamber fit. Starting with either the minimum load quoted OR the smallest that gives a velocity that will meet your needs (legal hunting energy). Produce batches of at least 5-rounds with incremental increases in powder charge of half a grain (increase the increment to one grain for very large capacity calibres with more than a total charge spread of 8-grains). At this stage, DO NOT assemble a batch using the maximum quoted charge weight, or the next lower one as they may not be necessary or worse, could be dangerous in your rifle. Unless you already know the optimum figure for your rifle, seat the bullets to the Cartridge Overall Length (COL) quoted for that specific bullet. Make sure that you notate the batches in an easy to recognise manner, colour coding the case or bullet.

Test fire the ammo at a representative distance (100 yards probably) and supported for maximum consistency. Apply a consistent cleaning regime to the rifle between batches. Check the primers after firing each successive batch, signs of cratering or bursting indicating excessive pressure. A sticking bolt or noticeable increase in recoil are also signs that we have reached a maximum limit. DO NOT fire any remaining batches that have larger charges. Examination of the targets should reveal a tightening of the group size as we progress up the level of charge and then increase again as we approach maximum safe pressure. Note that the two or three charges that gave the best groups. If all the groups look similar, we need to change another variable.

Assuming that we do have a change of group sizes and the ammo was loaded to the specified COL, we can look at the effects of changing that dimension. DO NOT change the seating depth without reference to your actual chamber dimensions. Using the chosen bullet and an un-primed, empty case from the batch, seat a bullet long in the neck, marking the bullet wall with either a felt tip or smoke. If the bullet is loose then gently crimp the neck. Carefully chamber the round and ease the bolt shut. Open the bolt and catch the extracted round.

It should have a serrated ring around the ogive, indicating the engraving marks of the rifling. Measure the overall length of this round. This is the NON-EXCEED length for a cartridge with that SPECIFIC bullet. Make a note of it and keep it safely with the dummy cartridge. Now, assemble new 5-round batches of the selected powder charges from the earlier test, seating the bullet to an overall cartridge length that is .006” LESS than the dummy round. Repeat the test firing under the same conditions as before. Try the same process again, this time with the length reduced by .012” and then again by .018”. (Small changes can have large effects!).

In a few instances, a cartridge/rifle combination works best with the bullet in the engraved position; NO BULLET JUMP. However, this can lead to a significant increase in pressure and tests should therefore be commenced with reduced loads, again working up later batches with increased charge weights whilst applying the same visual and physical checks as before. If you’re unhappy with the results obtained, then we need to be sure that the rifling and muzzle crown are in good condition and that the rate of twist has been correctly measured. If the rifle passes all these tests, then we should consider a slight increase or decrease in the weight of the selected bullet, staying with the chosen propellant for now. If all of these measures fail to achieve acceptable results, then we need to compare the barrel length with that of the arm used in the tests. If ours is shorter, then a faster burning powder may improve results. For a longer barrel we may wish to select a slower powder from those listed for this calibre/bullet combination.