Lee Lead Hardness Testing Kit

-

395

Comments

Comments

- Last updated: 22/05/2018

In simple terms, different types of guns require a different hardness of bullet. Pure lead, for example, is at the soft end of the bullet hardness range and is recommended for use in muzzle-loading guns. At the other end of the scale is linotype, an alloy of lead, tin and antimony, which is more suited to higher velocity guns, up to maybe .30-06 calibre. While both metals have uses in bullet casting, their applications are definitely not interchangeable. Using bullets that are too soft will cause excessive leading of the barrel; whereas using bullets that are too hard will cause pressure problems, amongst other issues.

If you cast your own bullets, the hardness of the bullets you make is significant and it is difficult to produce bullets with a consistent hardness, batch after batch, without some form of testing. The Lee Lead Hardness Testing kit makes it possible to test and compare the relative hardness of different bullet alloys, giving the bullet caster the opportunity to alter the make-up of an alloy to achieve the desired hardness. In order to quantify the relative hardness of different metals the Brinell Hardness Number (BHN) is used. On this scale, pure lead is a number 5, while linotype is 22. Comparing BHNs for different metals might mean little to the average shooter, but it does give a comparative scale to work within.

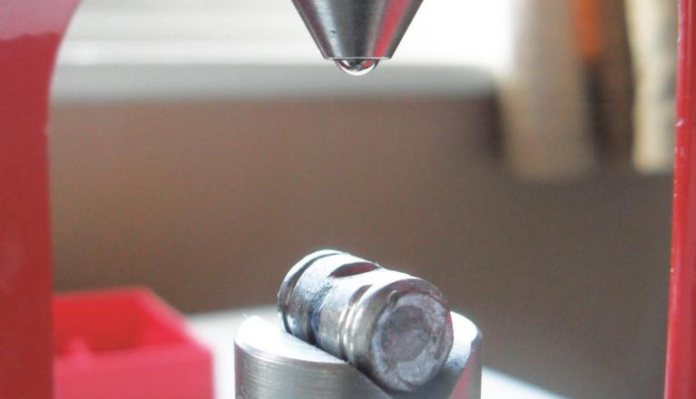

The kit includes an indenter tool, a 20-power microscope and a v-block cradle to hold the bullet being tested. The indenter is simply fitted to a single stage press and the v-block is installed on the top of the ram like a standard shell holder. To test a bullet, you first need to file a flat area on the side of the bullet, where the indenter will make contact. This is a bit fiddly to do on the v-block and is actually best achieved in a vice. Once the bullet is in place in the block, the ram is raised, so that the ball indenter makes contact with the flat area filed onto the bullet. Additional pressure is then applied until the top of the indicator rod, which is recessed into the top of the indenter, becomes flush with the top surface of the indenter tool. This pressure is held for 30-seconds and then released. If too much force is applied, the top of the indenter rod will stick up out of the indenter tool and the impression created will not be an accurate representation of the bullet hardness. The diameter of the indentation created in the bullet is then measured using the microscope, which has a graduated measure on the lens. This measurement is then looked up on the hardness chart included with the kit and the corresponding BHN read off. The chart also includes the strengths and max pressures for the BHN, so it is possible to match the bullet to the correct pressure from the reloading data being used. This gives you some extra reassurance that your bullets are safe for the intended powder charge and calibre.

The kit is very easy to use and the supplied instructions are up to the high standard you can expect from Lee. The only part of the process that takes time to master is reading the diameter of the indentation with the microscope. You have to get your eye at just the right distance from the microscope and make sure the bullet surface is adequately lit from the side where the microscope body is cut away. This can take time to master but it is worth persevering.

Getting an accurate reading can be tricky, due to the very small measurement you are taking and in practice it proved beneficial to carry out the test a number of times on each bullet and take an average of the measurements. This seemed to give a better representation of the bullet hardness and the average of the measurements that I took certainly seemed to reflect the correct approximate hardness of the materials being tested. I have some excellent wadcutter bullets from the Shellhouse Bullet Company in Lancashire and they actually include a BHN on the packaging. The box showed a BHN of 15.4 and when I tested one I got an average indent diameter of .057, which corresponded with a BHN of 16.0, which is pretty close to the manufacturer’s figure. I also tested some linotype that I have and that gave a reading of .048, corresponding with a BHN of 22.7, again pretty close to the actually BHN for linotype, which is 22.

This is another really useful tool from Lee and is very well made. In each test, the BHN generated came pretty close to the published figure for the material being tested and the results were consistently reproduced when the test was repeated. If you cast your own bullets, and want to take bullet hardness out of the list of variables that affect the accuracy of your finished ammunition, this piece of kit is well worth investing in. If you buy your bullets and you are considering changing the brand you use, it is also a good way to test the various bullets available, to see if the hardness is comparable to your current brand.