Lily:

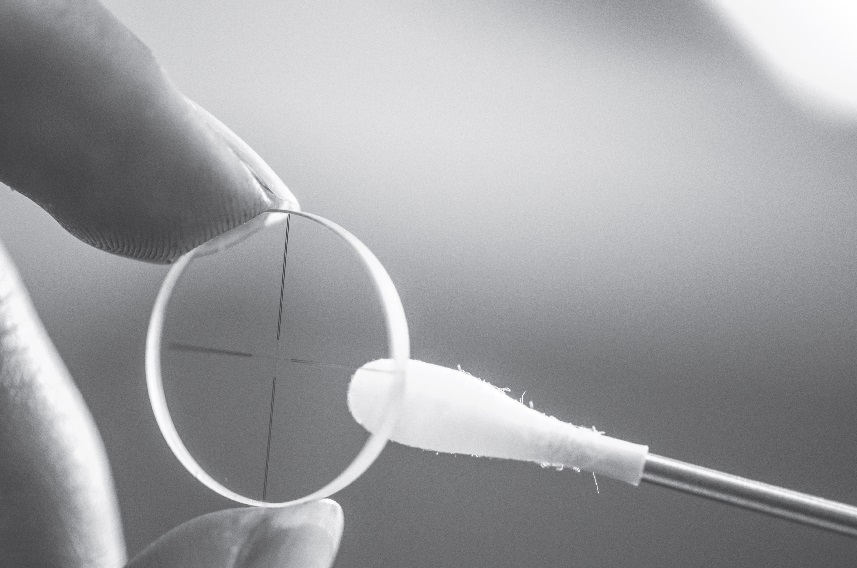

Yes, I believe the superiority starts from the ground up because as a family business

we design, develop and build the optics from prototype to the finished product. Our own

factory manufactures the optics meaning that materials and quality control are optimised to

the maximum. Alternatively, rivals use third party factories at a price point and a brand label

added at the end which means there is always a cost cutting element that is detrimental to

performance and durability.